A National Historic Landmark

Sloss Furnaces, Birmingham

Recently, Joyce and I went to Alabama to visit my brother and his wife. While there were toured the Sloss Furnaces National Historic Landmark. www.slossfurnaces.com

Sloss Furnaces was the largest manufacturer of “pig iron” in the world. It operated from 1882 until 1970. At its peak, it operated 5 blast furnaces and produced up to 900 tons of iron daily. The furnaces ran 24/7/365. The city of Birmingham was built on the iron industry and was a center of the Industrial Revolution.

The reason Birmingham had multiple pig iron furnaces was because of the close proximity of the materials needed to make the crude iron: iron ore, limestone, and coke (coal).

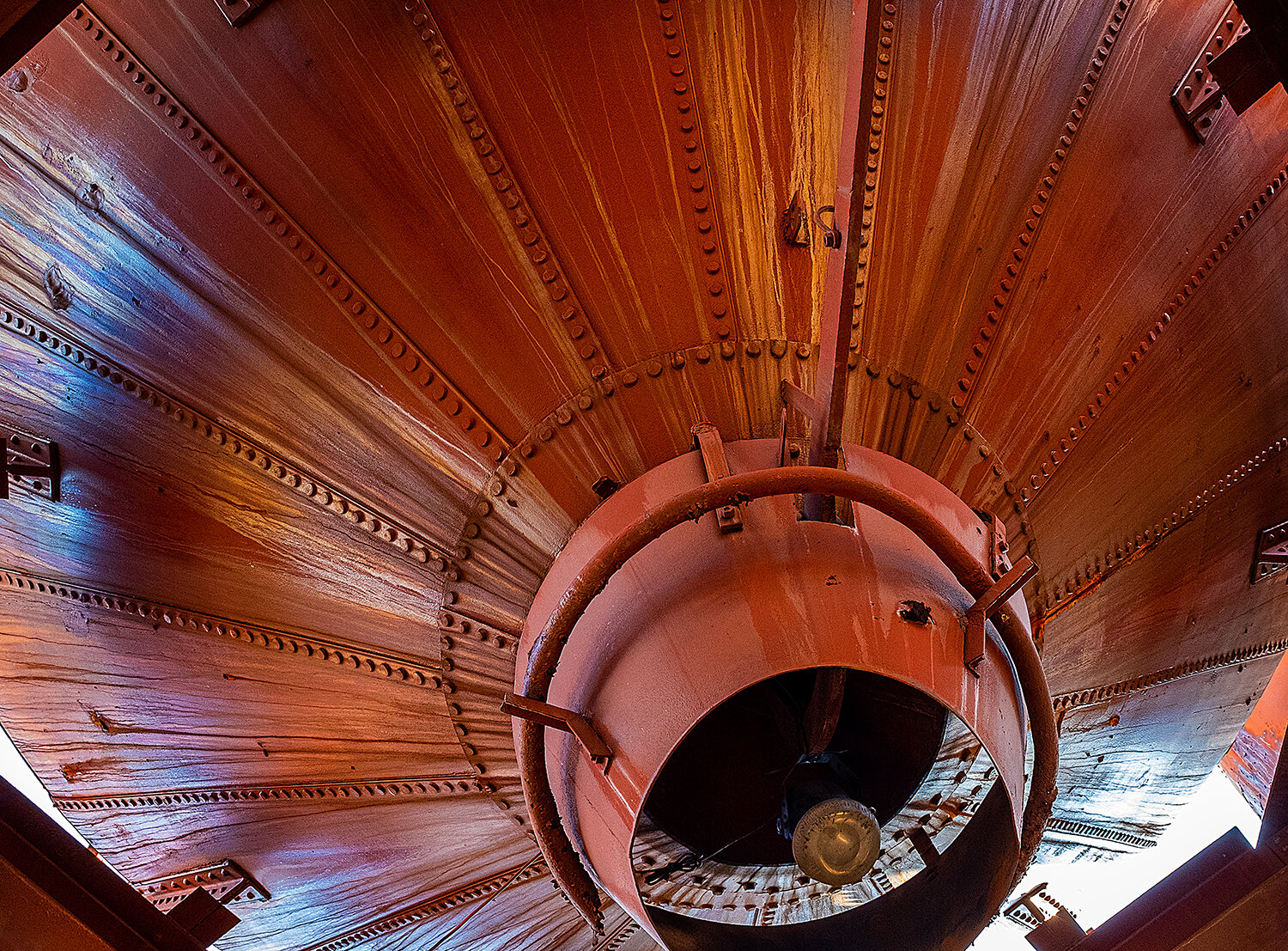

Large funnel

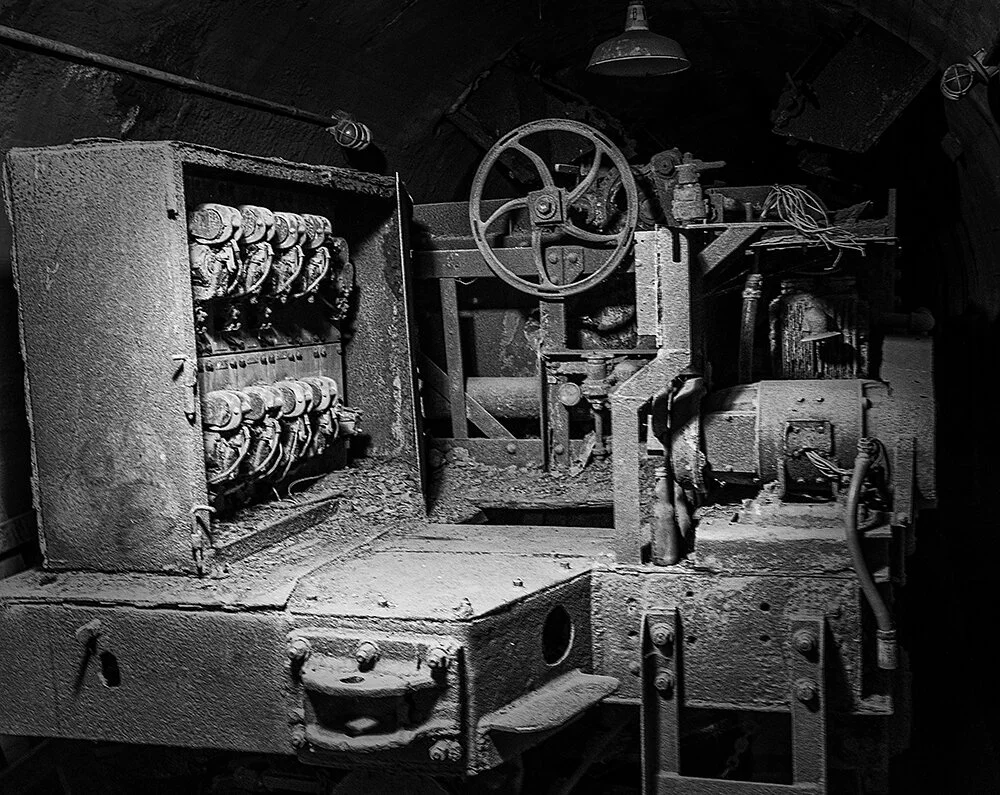

Control room where raw materials were brought in by train.

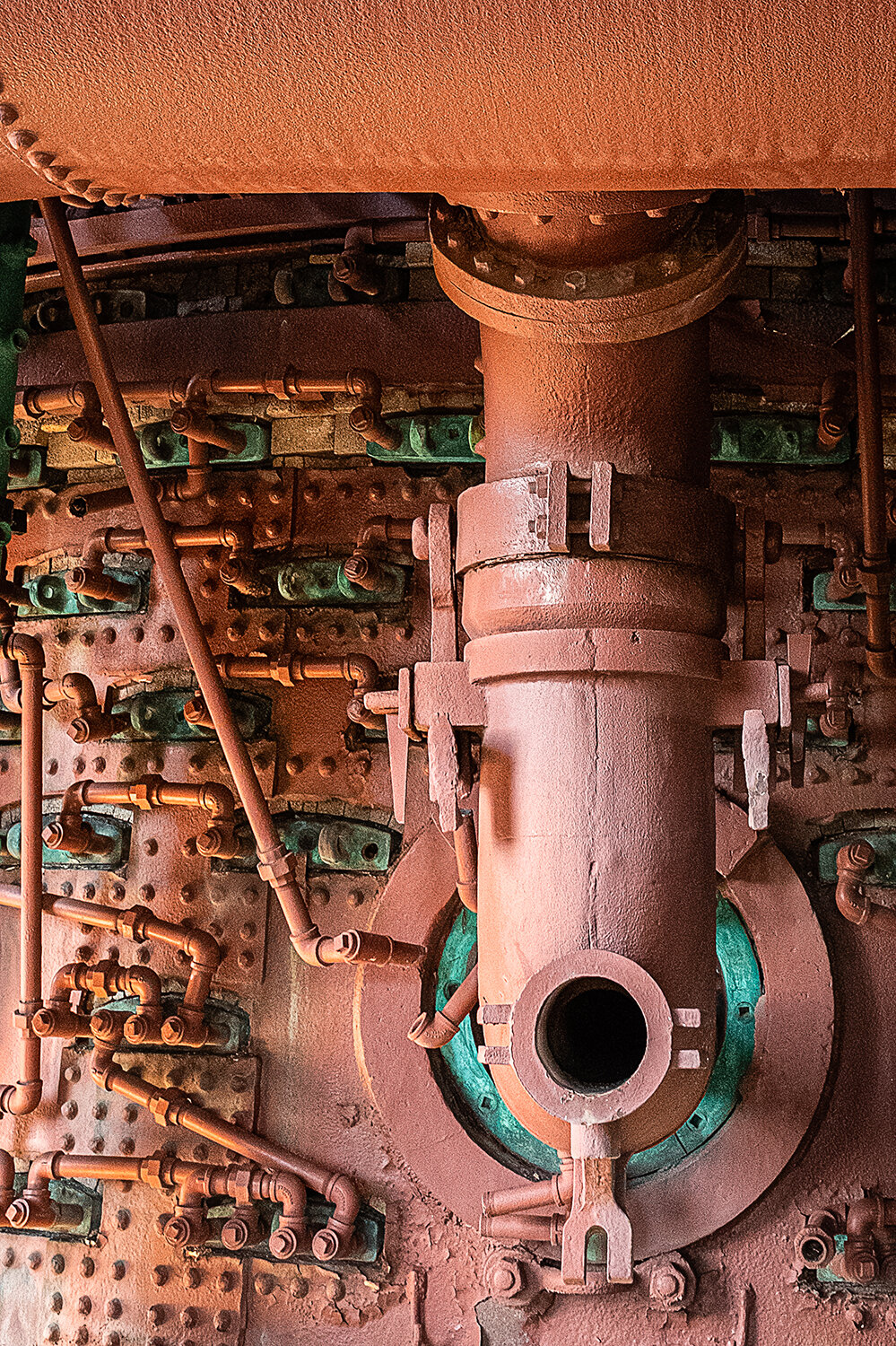

Furnace area - pipework

Pig Iron: solid form of crude iron obtained from smelting iron ore in blast furnaces. Pig iron is used as the raw material for cast iron products and steel manufacturing. The term “pig iron” dates back to the time when hot metal was cast into ingots before being charged to the steel plant. The moulds were laid out in sand beds such that they could be fed from a common runner. The group of moulds resembled a litter of sucking pigs, the ingots being called “pigs” and the runner the “sow”.

Furnace detail.

Furnace base.

Furnace towers.

The furnaces were a very dangerous place to work. Injuries included falling to the molten iron and being incinerated, carbon monoxide poisoning, bursting steam pipes, being pulled into massive gears/machinery.

The work was intensely laborious, hot, and dangerous.

Machinery in the blowing engine building.

Window and shadow in the power house.

Lift in the power house.

Furnace towers.

The images were taken while on a guided tour, with limited time, and were taken with hand-held camera. Fujifilm X-T2 camera with Fuji X 16-55mm f/2.8 lens used.

The facility offers occasional photography workshops which I hope to someday attend.

Check out their website (slossfurnaces.com) and other internet search for information if you want to learn more. Enjoy!!